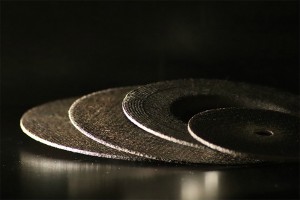

As a person who carries out metal works either professionally or personally, you have to have the perfect grinding wheel. This should be able to cut even through the most ferocious metals while providing you with the perfect finishes. However, getting the best grinding wheel is an overwhelming task. You can choose many brands, but some are more effective than others. You have to research to ensure that your work is in the best Cut off wheel’s hands in the market. This will provide you with remarkable and precise cuts that will deliver you the results you are looking for. Below, we have listed the best Cut Off Wheel for cutting metal. This equipment is a guarantee that you will achieve accurate and fast cuts while at the same time preserving the safety of the user.

Table of Contents

Best Cut Off Wheel for Cutting Metal Reviews

1.Duropeak 25Pack

DUROPEAK 25Pack is one of the best grinding wheels for steel. It is made from very durable material, making it last for a longer duration than most grinding wheels. It also comes with all the crucial features that will enable fast cutting and ensure no burr when it is in use.

This grinding wheel also offers you the most comfortable cutting that is not available in other similar equipment. The reason for this is that it has very low vibrations that make working with it easier. This means that you can work with it for longer hours.

One benefit that makes this grinding wheel stand out is the fact that it can serve multiple purposes. With it, you can cut different types of metals, be it cast iron, steel, or stainless steel. You, therefore, do not have to buy different equipment for different metal works.

Recommended for: This is best suited for those who have a diversified need for a grinding wheel as it can cut different types of metals.

- It comes with a fiberglass mesh that makes it rank highly on safety.

- It is very durable and highly resistant to wear and tear.

- The grinding wheel has a high-quality cutting capability.

- It also works great in saving time due to its fast cutting feature.

- It has a high and efficient maximum cutting speed of 80 m/s.

- They rank lower in terms of durability than other types of grinding wheels.

- The only way that you can prevent shatter is if you install a chip in the wheel.

2. WORKPRO 20-Pack cut off wheels

Workpro 20-Pack is one of the best angle Cut offs wheels for cutting metal that will save you the trouble of having to purchase a new one after only a few days. The reason for this is that it has been made using white alundum grain and corundum.

This grinding wheel will also offer you efficient and high-quality cutting. It has an ultra-thin design that enables free cutting while causing minimal metal loss. It also has a high-performance score owing to the great compatibility with different types of Cut offs.

Recommended for: This disk is perfect for those who are looking for precision and efficient cutting.

- It has a high safety score based on the double fiberglass mesh.

- It has a wide range of applications, which makes it convenient.

- It has a very long service life because of the highly durable corundum and white alundum grain.

- It is a very high-quality tool that cuts efficiently.

- They can easily attach, and this makes installation a smooth process.

- The disk can easily fall off, and this can cause a great safety risk.

- When the wheels are new, they may release a bad smell that could cause discomfort.

3, Makita 5 Pack

Makita 5 Pack has all the ideal features that you are looking for in a grinding wheel. It has the right-sized wheel dimensions that make it compatible with the four and a half-inch angle Cut offs.

The ideal wheel thickness makes it possible to cut high-quality metal. It also helps you to achieve precise cuts and give you the best-balanced cut life. It also makes it possible for you to work for longer, giving you convenience.

With this best Cut Off Wheel for cutting metal, you can also achieve fast and effortless cutting. It has a wide range of applications, as it can cut various types of metals. This, therefore, gives it a high-performance score.

Recommended for: For those looking for durability, then the Makita 5 pack is the perfect fit for them.

- It works perfectly with stainless steel material, as it does not cause rust or corrosion.

- It is a very durable wheel that gives it a longer life performance.

- It has a great heat buildup, which makes it last longer when cutting.

- It has outstanding quality as well as efficient cutting.

- With this wheel, you can remain safe, as it is equipped with great material that prevents wheel shatter and injury.

- It can cause some form of injury as it can result in sparks during use.

- If excess pressure is used, it can cause discoloring of the metal piece.

4. DEWALT cutting wheel

What makes Dewalt cutting wheels stand out is the fact that they are effortless to use. This makes them a go-to option for beginners. They are also highly durable, which gives the user the convenience of not purchasing a new one now and then.

It has also been proven to result in high efficient cutting as well as precision. The reason for this is the fats burr feature that will ensure that with this wheel, you get the best results in terms of metal cutting.

Recommended for: This grinding wheel is ideal for beginners because it comes with great usability features.

- They are highly durable, an aspect that makes them convenient.

- The fiberglass sheet can provide you with the safety that you need during cutting.

- The material mix of this grinding wheel can help you achieve a longer cutting time.

- They cut metal quickly and efficiently, which makes them rank highly in terms of performance.

- It is effortless to use, and this makes it great equipment for beginners.

- They can be slower than other grinding wheels, and this can reduce the workflow.

- They also release a lot of debris material during use.

5. Cutting Wheel 50 PCS Cut Off Wheel

This one comes in a pack of fifty pieces that you can easily interchange during use. It also means that you will be able to use this pack for a longer time than usual. The ideal thickness of this wheel also means that you will be able to cut through any piece of metal.

It has also been made from the best aluminum oxide material. This enables for more aggressive cutting, meaning that you will have more precise and efficient cutting. With the wide range of applications that this grinding wheel provides, you will have more convenience at work cutting through all types of metal.

Recommended for: These are also ideal for looking for a grinding wheel to handle a wide range of applications.

- The wheel has a wide range of applications, which makes it convenient for the user.

- With this wheel, you will also be able to cut aggressively through the metal.

- They are also highly durable as they can last for longer than other grinding wheels.

- It also helps to achieve quick and fast cutting.

- The wheel has the ideal thickness that makes it possible to achieve precise cutting.

- They can be slower in cutting metal as compared to other similar wheels.

- They fail to cut harder metals as efficiently as they can cut through softer metals.

6. Makita 10 Pack

Makita 10 Pack has the type one flat wheels that will cut through different metal and even stainless steel material. The standard wheel dimensions make this equipment compatible with four and a half-inch angle Cut offs.

It has a wide range of applications, and this gives great convenience to the user. It can cut through black steel, sheet metal, rebar, galvanized steel, steel pipe, etc. It can serve this purpose with minimal effort from the user and very fast.

Recommended for: Makita 10 Pack is the best grinding wheel for those looking for something that will provide them with high-quality cutting and precision.

- This wheel can provide you with accurate cutting for every task.

- It can also provide you with a high-performance score that will give you the precision in cutting you need.

- It can provide you with longer cutting, thus making it highly reliable.

- It is highly durable as it is resistant to wear and tear as well as shatter.

- With the thickness of this wheel, you will manage to cut consistently and precisely.

- It can be very thin, an aspect that may make it unsafe for use.

- They are only ideal for cutting light material, as heavy metals can be too heavy for this wheel.

7. GRAFF Diamond metal cutter

This metal cutter has gone through various tests to guarantee that it can provide the user with the best safety and functionality. These tests have proven that this equipment can provide the user with over 3000 cuts.

This grinding wheel can cut through various kinds of metal. These include dry cutting of various metal types, pipes, and sheet metal. However, it would help if you didn’t use this wheel to cut through very thick metal.

This best Cut Off Wheel for cutting metal can cut for longer periods, giving users convenience as they work. Unlike other grinding wheels, this wheel is highly durable and can remain resistant to wear and tear.

Recommended for: This grinding wheel serves best to those who are cutting softer and thinner metal types.

- With the 1.5 thin kerf-cutting wheels, you will be able to work on different types of metal.

- It is highly durable, and it does not wear down easily.

- It offers the utmost comfort to the user during use.

- It has high-temperature soldering, and this ensures that you can cut for longer.

- It has great safety features, and this makes it possible to cut without the risk of radiation.

- It is only ideal to be used in cutting rough metal as it can cause a blurred edge.

- They do not cut as fast as other disc types.

8. Black Hawk 25 Pack

The Black Hawk cut off wheel can cut for longer durations of time than other grinding wheels. With the thick edge measuring 1/16 inches, you will be able to cut for longer. This thickness will also provide you with the strength that you need to make aggressive cuts.

To guarantee the safety of the user, these discs also come with a fiberglass mesh. They are designed to be compatible with angle Cut offs, and they have a wide range of applications. This includes cutting various types of metals, slicing rebar as well as cutting angle iron.

Recommended for: With the longevity that this wheel provides, it is ideal for those looking for a wheel that can cut for longer periods.

- With the thick cutting edge, you can achieve more aggressive cuts.

- The fiberglass mesh can provide the user with safety.

- The thickness of the cutting edge adds to the durability of this grinding wheel.

- They can be used for a wide range of applications.

- They are highly efficient in providing you with quick and precise cuts.

- It is best suited for cutting through thinner metals.

- The cutting edge can sometimes be thicker than what is stated.

9. Benchmark Abrasives 50 Pack

This grinding wheel has been designed to provide the user with a longer wheel life with little chatter and fast cutting. With the great and standard dimensions that are provided in this equipment, you can achieve great performance.

They have a wide range of uses, making it a go-to grinding wheel for those who are into diversified metal cutting works. Therefore, it can be used to cut through steel, iron, stainless steel, and plastic.

One selling point that distinguishes this cutting wheel from others is the self-sharpening features. This makes it possible for the wheel to carry out aggressive cuts through various metals.

This grinding wheel is best for people looking for a wheel to provide them with aggressive cutting.

- These cutting wheels are highly durable to last over the years.

- They offer high quality cutting to deliver you high-quality finishes.

- They also have a wide range of applications as it can cut through various types of metal.

- It can provide you with aggressive cutting owing to the self-sharpening capability.

- The standard dimensions provide for more accurate and precise cuts.

- You have to wear your protective gear when using this as it can cause a lot of sparks and debris.

- The arbor may break off during use, which can cause danger to the user.

10. KSEIBI Metal stainless steel cutting disk

This cutting wheel is best suited for cutting both steel and stainless steel. It can be used for very aggressive cutting to ensure that a user will achieve the results they are looking for. The design also makes it possible for fast and high-quality cutting.

When this cutting wheel is used to cut through normal steel, it can serve you for longer periods. This, therefore, means that as a user, you have to restrain from using this wheel to cut through hard and thick metals.

This grinding wheel is best suited for people looking for comfort during cutting, as it does not emit any vibrations.

- It has a longer service life if it is used to cut through normal steel.

- It has a fast cutting feature that provides for minimal burr as well as durability.

- They are highly efficient in terms of metal cutting as they deliver high-quality results.

- They can precisely cut through steel without the production of toxic smells.

- This grinding wheel is also comfortable to use, as it does not produce vibrations.

- It cannot be used to cut through tough and abrasive metals.

- They can also tend to be a little bit slower than other cutting wheels.

Factors to consider when buying

You will have to consider several factors when selecting and choosing the best grinding wheel for steel. This is to ensure that you get the right one that will best handle the task at hand.

Safety

Before anything else, safety should come first. This means that your selection of a grinding wheel should depend on how highly it scores on the safety chart. When you are grinding, your body is exposed to a lot of potential injuries. You do not want to lose your hands or any of your body parts when working. Make sure that the grinding wheel you select can provide you with 100% safety. You can do this to make sure that you are using it for the right purpose. If you are looking for a grinding wheel that can be used to cut aggressively through ferocious metal, then a lighter one can be dangerous. Also, make sure that you get other previous users’ views on their user experience.

The abrasives

The other factor that you should consider is the types of abrasives. This is because every abrasive type will provide you with a different toughness as well as strength. Abrasives are made using different types of chemical elements and compounds. This is to ensure that it can cut smoothly over any metal that is provided. Various chemical formulas can be used to make wheels that can cut into the hardest of steel, while there are those wheels that can be used to cut through soft steel. A closer study of the abrasives will give you the information you need to analyze the wheel’s effectiveness to cut through your workpieces.

Longevity and durability

Another factor that you should consider before making your purchase is longevity and durability. Longevity comes in when you use the disc for a long time, and this is made possible by the heating capability. When a disc has a longer life, it can last for longer periods during cutting, giving the user convenience. In terms of durability, a longer-lasting disc will also add to user convenience. This is because you will not be required to purchase a new one in only a short while. The statistics on the same can also be gotten from the product details as well as user testimonials.

Final verdict

When you have the right grinding wheel, you will handle your metal cutting tasks more efficiently and quickly. Like any other equipment, you have to ensure that your grinding wheel has all the right features that make it perfect to handle any task. While most grinding wheels can cut through all types of metal, their effectiveness on this varies. TThosediscs tan cut through the toughest metals, while some are ideal for softer metals. You have to carry out due diligence to evaluate the suitability of one to discover the other.

Frequently Asked Questions

What is angle Cut off discs made of?

Angle Cut off discs are installed in an angle Cut off to help in cutting various types of metals like steel, aluminum, or stainless steel. The major materials that have been used to make these discs include fiberglass mesh, abrasive material, or other types of organic resins. The materials are subjected to heat and pressure, and this then makes them efficient in cutting. Depending on the material used, a disc can cut faster or slower, while some can cut softer metals and other harder metals. These discs also come in different thicknesses, and choosing the ideal one is dependent on the metal piece that you want to cut.

How to change an angle Cut off disc?

When you notice that your blade is becoming blunt and ineffective, then it might be time to change it. On the angle Cut off, there is the blade lock button. Press this button and do not let go. Make sure that you have a wrench nearby. Most of the angle Cut offs come with their wrench. While still holding in the lock button, use the wrench to rotate the arbor’s nut in an anti-clockwise direction. After the nut is loose, take it out and then remove the old blade and place the new one. Fasten the bolt in place and make sure that it will tighten enough.

How to install angle Cut off disc?

Installing a new angle Cut off disc can be a challenge, but with a little bit of care, you might be able to do it yourself. Study how the old one was placed before removing it first. Please place it in the same position with the new disc in hand that the previous one was. The next step is to tighten the bolt and secure the disc in place. When installing a new disc, there are several factors that you have to consider. First, you should make sure that the nut is tightened well enough and that you are using a disc that is compatible with the Cut off.