A well-kept lawn enhances your curb appeal. It also gives you a sense of ownership and the feeling of being infused with nature. To achieve these statuses, you need a lawnmower that is always in perfect running condition. Sharp lawn mower blades increase your grass cutting efficiency. Besides, they provide a clean cut each time. To keep them sharp, you must have the best grinding wheel for sharpening lawn mower blades. Buying new lawn blades frequently is not only expensive but also frustrating.

If you are to maintain a high-quality lawn, you must invest in the best grinding wheel. However, choosing the best one calls for expertise. One thing is sure, not every homeowner is a professional in these things.

To cut you the slack, we have researched extensively. You need not spend painstaking hours browsing through an endless stream of websites. Doing so is like looking for a needle in piles of hay. We have reviewed the ten best grinding wheels and are confident you will find one for your lawnmower blades.

We have simplified the technicalities in a way that is easy for an ordinary landscaping enthusiast to understand. Please proceed and be sure to pick the right grinding wheel.

If you are in a rush, these are our top three recommendations.

| Preview | Product | Rating | Price | |

|---|---|---|---|---|

| United Abrasives-SAIT 20063 A24R General Purpose/Long Life Grinding Wheel (Type 27/Depressed Center)... | 65 Reviews | $68.00 | Buy on Amazon |

| WORKPRO 20-Pack Flap Discs, 4-1/2-inch, Arbor Size 7/8-inch, T29 Zirconia Abrasive Grinding Wheel... | 1,171 Reviews | $26.99 | Buy on Amazon |

| Makita 10 Pack - 4.5" Grinding Wheel For Grinders - Aggressive Grinding For Metal - 4-1/2" x 1/4 x... | 257 Reviews | $24.99 | Buy on Amazon |

Table of Contents

Best Grinding Wheel for Sharpening Lawn Mower Blades Review

1. WORKPRO Flap Discs

The WORKPRO Flap disc pack contains ten pieces as follows: 10 (40-grit), 5 (60-grit), 3 (80-grit), and 2 (120-grit) grinding wheels. The wheel variety shows that you can grind metal, wood, or concrete, hence the perfect choice for lawn mower blades. The discs feature zirconia alumina as the abrasive material. Zircona alumina is durable and enhances the longevity of the grinding wheels.

Besides, the WORKPRO Flap Discs feature a fiberglass backing plate for preventing contamination of the blade surface. Again, fiberglass absorbs vibration during grinding. More so, angled flaps ensure that you sharpen the angled blade edges while also reaching contoured areas with ease.

Also, this grinding wheel pack has an arbor size that makes it fit in high-speed angle grinders. They can run at speeds of up to 13,000 rotations per minute (RPM) without getting damaged. Also, they do not smear while in operation.

- No vibrations during rotation on grinding machine

- Uniform grit on the disc surface

- Wide range of grinding options

- Exerts low pressure on the grinder

- Re-usable for less aggressive work when worn out

- Grit size printed on a paper sticker, which comes off moments after the commencement of grinding. The better option would be to print on the disc.

- The arbor size may not fit in all grinding machines.

2. Makita 4.5-Inch Grinding Wheel

Available in a pack of ten, the Makita Grinding Wheel features a combination of grain grit and a solid bond matrix for longer grinding. Also, the generous wheel thickness cushions the wheel from quick wear. A hard bond matrix completes the combination resulting in high precision. As if that is not enough, these features help moderate your electric power utilization.

What’s more, aluminum grain on the grinding wheel makes it ideal for stock removal. As if that is not enough, the Makita Grinding Wheel has a synthetic resinoid bond that makes it withstand high rotation speeds. Again, when grinding lawn mower blades with aggression, the wheels can handle it without breaking.

Each wheel has a thickness of 0.25 inches and a cutting diameter of 4.5 inches. Its grit rating is 24, which is an ideal standard for metal grinding. The wheel boasts of a low buildup of heat. Beyond this, the grain grit provides more grinding capacity than other competitor wheel brands.

- Perfect wheels for aggressive grinding

- High performance with an excellent job all around

- Generous width

- Their wear is proportional to usage.

- Produce less noise and reduced vibration

- Expensive disc compared to competitor brands.

- Buyers keep getting one grinder shipped instead of the 10-pack.

3. KSEIBI Aluminum Oxide Auto Body Flap Disc Sanding Wheel

The KSEIBI Aluminum Oxide Flap Disc features a 60-grit style specific for grinding steel alloys. Its design provides a wide range of tasks including, grinding, cleaning, rust, and stock removal. Other than steel, you can also use the flap disc on paint and rust. The grinder also does a perfect job on non-ferrous metals.

Thanks to the Aluminum oxide grain, the KSEIBI Flap Disc is hard and lasts long. Furthermore, the grit powder can penetrate the hard metal resulting in sharp and efficient lawn mower blades. More so, flap discs grind surfaces in a single step, an aspect that saves you time.

Each pack you order comes with 10, type 27 grinding wheels. The wheels have a three-dimensional structure. Here you will find layers coated with abrasive material and flaps reinforced with fiberglass. As each layer wears away, it exposes new abrasive material, ensuring a consistent cut all around.

- Abrasive grain material on the disc gives a wide scope of options.

- Cuts the target metal layers without damaging the material underneath

- Provides an aggressive cut hence boosts work efficiency.

- Wear down evenly towards the middle

- Has angle flaps that aid in wheel positioning

- Requires a user to apply much pressure on the grinding surface

- They cause paint clogging when used for paint removal.

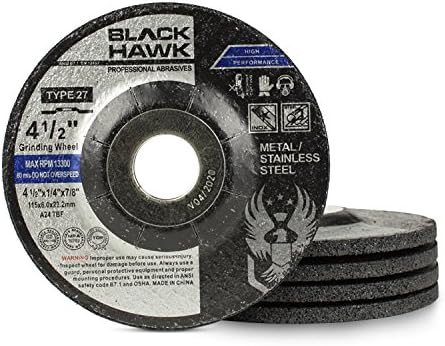

4. Black Hawk Depressed Center Metal Grinding Wheels

The 4.5’’ Grinding Wheels feature extra coarse A24T aluminum oxide grains. These are ideal for the removal of high stock from lawnmower blades. Also, a reinforcement of mesh made from fiberglass enhances your safety during grinding. Regarding longevity, they can last long beyond what the industry provides.

The wheels have a diameter of 4 ½ inches and a thickness of ¼ inch. Their arbor measures 7/8th of an inch. Besides, each of the grinding wheels fit perfectly on angle grinders. Their design makes them ideal for working on metals such as steel, stainless steel, iron, and ferrous metals. It can work at a capacity of 13,300 maximum rotations per minute (RPM) without damage.

Upon ordering, the package comes with five grinders meaning you have enough back-up. If one gets damaged, you can replace it quickly and proceed with your work. It saves you time too. Imagine having to place a fresh order and waiting for delivery.

- It is swift at cutting and grinding.

- Can withstand heavy grinding without breaking

- The wheels fit perfectly on angle grinders.

- The wheels balance well and do not vibrate even at top speed.

- It does not clog during use.

- It becomes less efficient when used beyond the 15-degree angle.

- Only good for flat grinding surfaces

5. POWERTEC 15505 White Aluminum Oxide Grinding Wheel

Aluminum oxide is the main material on this grinder and befittingly bears its name. Unlike other types of wheels that operate with handheld angle grinders, this is a stationary bench grinder. It has a diameter of 8’’ and a thickness of 1’’ while its arbor size is 5/8’’. More so, the grinding wheel has a coarseness of 120 grit.

Moreover, vitrified bond technology used in making this grinding wheel equips the product for robust applications. The wheel’s design ensures that it works on steel material with ease. It cuts metal grains fast and does not damage your lawnmower blades.

Thanks to fast cutting and heat dissipation, the Powertech grinding wheel does not de-temper your tools. Besides, the premium-vitrified bond structure on the grinder offers you enough surface for tool-to-grinder contact. As if that were not enough, the wheel leaves behind a clean surface owing to sections of the grains shedding off.

- Grinds metal surfaces smoothly, resulting in sharp edges.

- Correctly sized arbor

- Compatible with most bench grinders

- It leaves behind a beautiful finish on lawnmower blades.

- Grinds highly sturdy steel surfaces as well as those sensitive to heat

- It has small chips on its surface.

- Has a slightly oversized hole resulting in vibrations during operation.

6. Merryland Expert-line Cut Off Wheel

The Merryland Expert-Line Cut Off Wheel grinder has a diameter of 4 ½’’ and a thickness of 1/8’’. Its arbor is 7/8’’. The wheel features double reinforcement for accurate cutting at high speed. More so, the tool is suitable for materials that include steel and iron.

It is designed for use on angle grinders. If you are looking for the best grinding wheel for sharpening lawn mower blades, the Merryland is a perfect choice. Apart from lawnmower blades grinding, you can utilize this sharpening component for other cutting tasks. Whether you are a do-it-yourself enthusiast or an industry worker, the Merryland Expert-Line Cut-off wheel does not disappoint.

Depending on your preference, you can procure a 25 or 10-piece box. These should last you a while before replenishment. Moreover, the product comes with a safety guide, which is a bonus. At the same time, you have a choice of different sizes. No matter the task that comes up your sleeve, there is a grinding wheel ready.

- Endures tough materials

- Sharpens blades with a clean finish

- It does not wobble on the angle grinder.

- Have low dust emission during operation

- It cuts fast and accurately.

- Cannot handle heavy grinding work

- Disintegrates fast.

7. LotFancy Flap, Grinding, and Polishing Discs Set

The discs come in a pack containing 11 pieces. Each of the 4.5 Inch Flap Discs & Grinding Polishing Discs in the set features fiberglass reinforcement for vibration absorption. Furthermore, fiberglass adds to the grinding wheel’s durability.

The assortment also contains Strip Discs for paint and rust removal. With these, you can work on the target material, confident that there will be no damage on the original surface. On the other hand, the Nylon Polishing Disc helps polish the metal surface and do the finishing touch. Felt Buffing Discs are also a part of the package. These perform similar tasks as the Nylon Discs.

Overall, Flap Discs carry out heavy sanding at high speed resulting in fast results and long-lasting blade sharpness. One advantage of this grinding and polishing kit is that it not only helps keep your lawnmower blades sharp but also clean. All the discs in the pack can fit into most 4.5’’ angle grinders.

- Provide superior cuts on materials

- Remove stubborn stains and rust with ease.

- Three-in-one grinders that do a fantastic job

- Wholesome variety derived from the assortment

- Contain bonding material that absorbs vibration

- Disc centering imperfect resulting in grinder vibration

- The wheels tire your hands on the grinder

8. S SATC Grinding Wheel Sanding Discs

S SATC Grinding Wheel Sanding Discs come in a pack of twenty. Ten of these are 40 grit, while another five have a coarseness of 60. Three pieces are of 80 grit, while the remaining two are of 120 grit. Different grit measures ensure that you have a grinding wheel for light or heavy sharpening.

All the sanding discs in the pack have a dimension of 4 ½ inches by 7/8 inches. The grinding wheel package features zirconia alumina, which is a hard and durable material. Besides, all the sharpeners have fiberglass coating for added durability.

The variety of discs in the package ensures that you can use these wheels for numerous applications. These include metal, woodwork, and concrete. Apart from sharpening, the sanding discs are appropriate for applying finishing touches on stone or concrete. Other capabilities include rust removal, welding seam clean-ups, chamfering and deburring.

- The product comes packaged in a cardboard box.

- Abrasive material suited for grinding metal fabrication and welds

- A pack of 20 with a selection of 40, 60, 80, and 120 grit for different applications

- It comes with a back-up for each type; 10-40 grit, 5-60 grit, 3-80 grit, 2-120 grit.

- Produces high standard cutting

- Poor packaging could get better.

- Not suitable for flat surface grinding

9. United Abrasives-SAIT 20063 Type 27 Depressed Center Grinding Wheels

The United Abrasives or A24R grinding wheels have heavy-duty fiberglass reinforcement. The added layer strengthens the material and protects it from wear. Besides, they contain aluminum oxide grain as the abrasive material. More so, the product contains no filler grain. Aluminum oxide has a reputation for consistency and high stock removal.

More so, the wheel hubs feature a combination of mechanical and chemical bonds. Both aspects make the grinding wheels free from vibrations. Grinding should be at an angle of 30 degrees for the best result. Moreover, the setting provides safety to users. The product is a type 27 grinder with dimensions of 4 ½ by ¼ by 7/8 inches. Each package contains 25 pieces.

Furthermore, the manufacturers provide a warranty that covers replacement for defective products. The company also offers to refund the purchase price if a buyer lodges a claim within six months after purchase.

- Grinding wheels coated with the right abrasive for high stock removal.

- Well reinforced to prevent vibrations.

- Suitable for both industrial and small-scale applications

- A consistent rate of metal removal during sharpening

- The wheels easily cut through heavy material.

- Wasteful for users with minimal sharpening to do

- The disc pad can easily tear into two.

10. Zirconia Flap Disc Grinding Wheel By Benchmark Abrasives

The 10-pack grinding wheel can work on different types of metal. You can use the disc to grind, blend, or apply finishing touches. It features a 40-grit surface for weld blending, beveling, edge chamfering, and heavy stock removal. Besides, the 40 grit is perfect for fabrication work.

With zirconia alumina as the grain material, the flap disc grinding wheel has one of the best cut rates to cost ratio. What’s more, blending zirconia with aluminum produces a sharpening tool that effectively removes burrs, beveling edges, and mill scale.

Additionally, the Premium Zirconia Flap Disc Grinding Wheel cuts metal quickly. As if that is not enough, it does not build too much heat, which would make it break. The disc does not leave behind deep scratches, as is usually the case with other grinding wheels.

- Provides maximum contact with the work surface

- Achieves way faster grinding

- Wears evenly hence effective

- It does not vibrate during use.

- Discs contain 40 percent more abrasives than other brands.

- It does not spin smoothly as compared to similar competitor brands.

- Not ideal for polishing.

Factors to consider while buying Grinding Wheel for Sharpening Lawn Mower Blades

Before purchasing grinding wheels, take time to research the types available. Also, widen your scope by finding out and comparing the prices. Here now are factors that you will find useful in your quest:

Make quality of your guiding star.

Whatever your lawn maintenance needs are, the truth is that finding the best grinding wheel for sharpening lawn mower blades requires expertise. Quality should be your first concern. Grinding wheels come in different varieties. Some are cheap, while others are pricey. Overpriced grinders are not necessarily the best quality.

Work with a list of possible choices.

As you exercise due diligence, list a few grinding wheels that you think are worth purchasing. Armed with the note, find reviews of these products. Pay attention to the pros and cons. A report such as this one can be of great help.

Think usability and comfort

Usability is the other important aspect. Consider whether the sharpener will run on an angle or bench grinder. More so, consider how you use your hands. Are you left or right-handed? Either way, seek a sharpener that will not make you feel uncomfortable during use. Also, look for a grinding wheel that requires less effort but with more efficiency.

Go for longevity

By investing in a grinding wheel, you express a desire to enhance your lawnmower’s useful life. Therefore, you must shop for a sharpening tool that lasts long. It should deliver the intended value for the money you pay during purchase.

Rotational speed

Fast sharpening is another critical factor during purchase. Each time you think of sharpening the lawnmower blade, you want the process to take the shortest possible time. Moreover, if the sharpening tool moves too fast, you may be unable to cope with it. Similarly, high acceleration could easily damage your lawnmower blade.

Packaging

Seek grinding discs that come in packs of, say, five or ten pieces. That way, if one breaks midway through sharpening, you can quickly replace it with another. Also, the discs must be compatible with your angle grinder.

Other Considerations – Safety Kit

As you shop for lawn mower grinders, perhaps it is also time to evaluate your safety. Do you have eye protection equipment? Are your gloves intact, or might they require replacement? What about sound protectors? All these are a must-have in your mini-workshop. Ensure that your safety kit is well stocked.

Final Verdict

The best grinding wheel for sharpening lawn mower blades is out there. From our review, we can ascertain the one that would serve you best. While researching lawn mower blade sharpeners, we came across top quality products. Deciding upon one out of the ten was not easy.

Nonetheless, we felt that the S SATC Grinding Wheel Sanding Discs 20 Pack Flap Disc pack was the best fit. The product packs flap discs of varying grit sizes. No matter the stubbornness of your lawnmower blade, these grinding wheels will get the job done. Besides, the product supports a variety of applications. When you are not sharpening lawnmower blades, you can work on other tasks.

Frequently Asked Questions

What Is a Grinding Wheel?

A grinding wheel consists of a combination of materials that create an abrasive surface. The wheel performs two fundamental tasks, smoothing or cutting. If you have a workshop at home or work in the manufacturing industry, you are already familiar with this tool. Abrasive minerals in the wheel not only shape or create perfect finishes on metal but also sharpens it. Early grinding stones used quartz grains as the abrasive material. Later, emery became the main element used in cutting and shaping. However, problems in obtaining the mineral coupled with its diminishing quality resulted in the discovery of corundum. You can find a grinding wheel of choice as there is a wide variety in existence. In your small workshop at home, the grinding wheel will efficiently sharpen lawn mower blades.

What is a Type 27 Grinding Wheel?

The Type 27 grinding wheel features a depression at the center. The design aspect is meant to allow the lock nut of a grinding machine to hold the wheel firmly. The layout of the type 27 abrasive wheel conforms for grinding tasks at right-angles. They perform heavy applications such as rough blending and stock removal. Also referred to as the Depressed Center or Raised Hub Wheel, this tool can also operate at angles of 25 to 35 degrees. The wheel can grind metals such as steel, cast iron, aluminum, and non-ferrous metals. It also cuts stone, ceramics, terrazzo, and concrete.

How to Dress a Grinding Wheel With a Diamond Dresser?

One way to keep your grinding wheel running at full efficiency is by using a diamond dresser. The tool helps in cleaning-up the buildup of particles. Other than cleaning, dressing a grinding wheel puts it back into its original concentric shape. A diamond dresser renews the edges, leaving fresh grains ready for the next round of sharpening. To dress a grinding wheel involves a series of simple steps. Pick the right tool. Find the proper diamond dresser for your wheel. To choose successfully, check the grit. The dressing tool’s grit must supersede that of your grinding wheel by a size or two. Switch on the grinding and let it run for a few moments. After ascertaining that it is rotating at its fullest, place the diamond dresser on the wheel. Begin by applying light pressure on the tool and increase it gradually. Maintain the compression until you notice that the grinding wheel has come to a stop.

How are Grinding Wheels Made?

To produce a grinding wheel, you will need a perfect combination of abrasive materials. The raw materials have evolved too. First, there was sandstone as the abrasive of choice before emery emerged. Later, manufacturers discovered silicon carbide. Eventually, the industry settled on aluminum oxide. The process involves mixing the ingredients. Depending on the manufacturer, some will mix all the raw materials at once. Others prefer to go a step at a time by combining the grains with the bonding material. After that, they take the abrasive through a second process whose purpose is to bond it. Next, they pour the mix into a molding machine. Finally, the manufacturer uses a hydraulic press to compact the wheel. However, grinding wheel designers must consider friability (the ease of a substance to fracture or break). By selecting the input correctly, the resultant grinding wheel attains its unique sharpening characteristics.

What are grinding wheels used for?

Grinding wheels are essential tools for making finishing touches, grinding and cutting metal. They achieve this by having abrasive particles on their surface. A typical grinding wheel has three elements: the grain, bond, and pore. The grain is the cutting edge, while the bond is like the glue that holds the grains together. As for the pore, it acts as the coolant for the grinding wheel. For effectiveness, the wheel must be in the rotation. Speeds vary depending on the task and material in question. As the wheel turns and encounters metal, the grains grind the workpiece thanks to friction. While grinding or cutting, the wheel releases abrasive particles. As you proceed, the release exposes the metal or other surfaces to the fresh grain. Eventually, the grinding wheel wears out, and you must replace it with a new one. Its lifespan varies depending on the nature of abrasive grain and how often you use the wheel.

How long does a grinding wheel last?

If you use a grinding wheel correctly, it can last you two years. Besides, to achieve this feat, you must also store the tool under the right conditions. Nonetheless, you should inspect and test a sharpening tool that you have not used in a long time. That way, you determine whether it is still reliable. After inspecting and testing, you come back and store the wheel. Later, you cannot predict how much longer you can use it. All you must know is that despite the longevity, grinding wheels do not last infinitely. You need to use grinding tools as practically as you can. Factors that affect a grinding wheel’s longevity include Quality: If weak, the grinder will not last you long Dressing: You must do it well; otherwise, you put the shelf life in jeopardy. Usage patterns: Always match the right grinding tool with the material in question. Grinding speed: Adjust the speed accordingly lest wear and tear occur unexpectedly.

How To Use A Grinding Wheel To Sharpen Lawn Mower Blade?

First, remove the blade from the lawnmower. The task involves a process where you unplug the equipment’s spark plug. After removal, use a socket wrench to remove the nut before sliding off the blade. You will notice that the blades are the chisel-type. One edge is flat while the other is angled. You only sharpen one side. Second, clamp the blade tightly in a clamp. The cutting edges are on opposite sides. Using a wire brush, remove all debris from the blade. Use sandpaper for stubborn remnants of grass and dirt. Ensure that the edge is clean; otherwise, you will wear the grinding wheel out quickly. Besides, you might end up exerting yourself unnecessarily. Third, put on safety glasses or goggles for protection. After that, pick your angle grinder and get ready to start sharpening. Run the grinder along the edge that needs sharpening. Flip the blade over and grind the other side.

What Are the Types of Grinding Wheel to Sharpen Lawn Mower Blade?

If you use a lawnmower for too long without sharpening its blades, it will tear grass blades instead of cutting them. You can tell dull blades just by looking at the grass. It appears rugged, plus you expose it to disease. Using a file as a sharpening tool will take you too long to finish the task. Grinding wheels make your work easier. Your choice of grinding wheel depends on the lawnmower blade type. For steel blades, you need a grinding wheel with an aluminum oxide grain. On the other hand, for a non-ferrous cutting edge, use a silicon carbide grinder. Therefore, you must first establish the type of metal on your lawnmower blade. You may use a bench grinder, but an angle grinder is the best. With bench grinders, you may find it challenging to attain the required angle. As for grit types, use anything between 40 and 60. Our review has a wide choice of grinding wheels together with the pros and cons of each.

When Should You Sharpen Your Lawn Mower Blade?

For someone that uses their lawnmower less frequently, you may find it hard to predict when next to sharpen the blades. However, ground keepers can quickly tell since mowing lawns is a part of their daily job. A lawnmower that roars into action once a week cannot have the same requirements as one that runs daily. For frequent users and do-it-yourself (DIY) homeowners, there is a rule of thumb that you can use effectively. Inspect the grass in your yard. If the cut is clean, know that your blades are still sharp. On the contrary, if the vegetation appears rough or has a chewed appearance, you need to sharpen the blades.

How do you Sharpen Lawn Mower Blades With a Bench Grinder?

Detach power supply to the lawnmower by disconnecting the battery and spark plug. That way, you will have killed the engine and erased any possibility of the lawnmower’s accidental engine start. In case you do not know where the spark plug is, locate the wire at the front or side of the engine. Once you find it, simply disconnect. Remove the blades from the mower. Turn the equipment on its side. Using a marker pen, put a mark on one side of the blade. Doing so helps in the correct reinstalling after sharpening. A wrench will come in handy when removing the cutter. After removal, clean the debris before attempting to sharpen the blade. Also, get ready by putting on eye protection goggles and gloves. Now you can sharpen the blade on your bench grinder. Hold the blade firmly and move it systematically against the grinder wheel.

Comments are closed.